Spray Coat running Track System Installation GuidanceIssuing time:2023-04-25 15:28 Job Site Inspection It is recommended to check and inspect the whole synthetic running track before doing the repair. Mark down with a chalk the impaired area and measure the size. Replacement Cut out and remove damaged area (like bubbles, color fading and delamination) and replace with synthetic track material. The replacement will not only cover the immediate affected area but also the adjacent area up to the nearest practical or natural break i.e. doorway or change of use area. Broken Area Color Fading Area Steps For Repairing Broken Area 1) Use ruler and knife to cut out the broken and adjacent area. 2) Clean the cutting area. And then check the ratio chart (Please refer to Bottom Layer Ratio Chart).

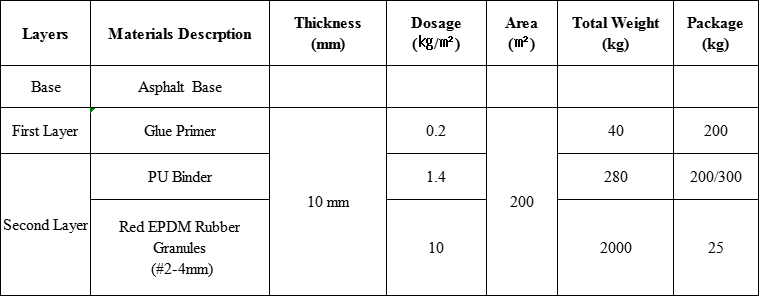

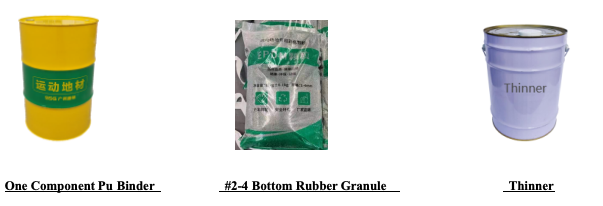

Bottom Layer Material Ratio Chart 3) Apply one component PU Binder by roller, 0.2kg/M². When the binder is dry, mix PU binder with EPDM rubber granules by ratio1:7, that is Pu binder : EPDM Rubber Granules= 1:7. To build a 10mm rubber granule bottom layer, mix 1.4kg of Pu binder with 10kg of EPDM rubber granules per square meter. If the PU binder is too sticky, add 1% to 2% of thinner. Material:

Machines and Tools:

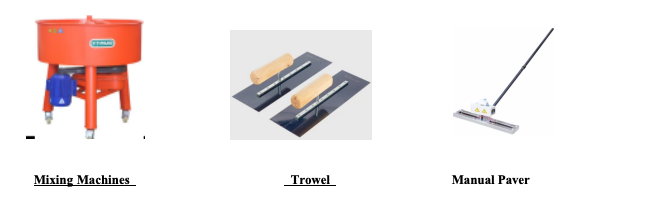

Installation Reference Pictures

Steps For Respraying the Track 1) Clean the existing track with high pressure spray water gun. And then expose the track to sun to let dry. 2) Check the material ratio chart (Surface Spray Material Ratio Chart)

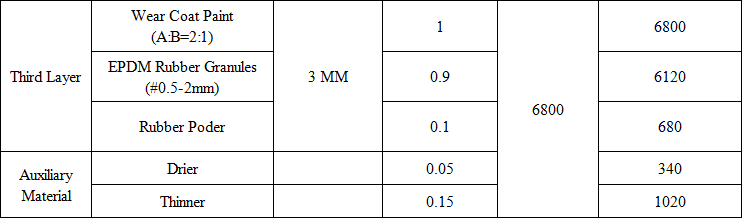

Surface Spray Material Ratio Chart 3) Roll Interface Agent onto the existing track to prepare for the spraying. 4) Cover near area with film to prevent contamination. 5) Spray two wear layers onto the existing track. First mix two component PU A with B by ratio 2:1 and then mix with #0.5-2 EPDM granules and rubber powder, consumption of per square meter is 1kg/m²of PU and 0.9kg/m²of EPDM, and 0.1kg of rubber powder, and then spray the mixture two times onto bottom rubber layer . (Add 1-2% of thinner and 0.5% to 1% of drier ). Material:

Machines and Tools:

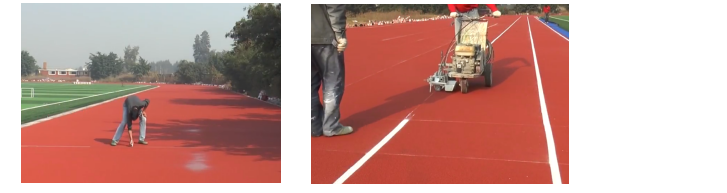

Installation Reference Pictures

6) Line marking. (mix the two cans(0.5kg+4.5kg) together and then do the line marking ) Material and Machines/Tools

Installation Reference Pictures

6.1) The line width is 50mm, tolerance<5mm 6.2) First fix the line point of each, then connect each point with the carpenter's ink marker 6.3) After the completion of line marking preparation, double check again to make the tolerance less than 2/10000. If more than this, should be corrected in time to ensure the accuracy of the line. |